As the name suggests, digital fabrication in architecture is the use of digital technologies to create physical models and prototypes. This can be done using a variety of methods such as 3D printing, CNC milling, and laser cutting.

Digital fabrication has become increasingly popular in recent years due to the many advantages it offers over traditional methods of manufacture. Firstly, it is much faster and more accurate. Secondly, it allows for a much higher level of customization, meaning that each prototype can be tailored specifically to the needs of the project.

Overall, digital fabrication is a highly efficient and versatile tool that can be used to create high-quality prototypes quickly and easily.

Digital fabrication is a process whereby architectural components are created using computer-aided design (CAD) and manufacturing (CAM) technologies. In this process, a three-dimensional (3D) model of an architectural component is first created using CAD software. This model is then used to generate instructions for a CAM-controlled machine, which fabricates the component from a material such as metals, plastics, or composites.

What is digital fabrication in construction?

Digital fabrication is a design and manufacturing workflow where digital data directly drives manufacturing equipment to form various part geometries. This data most often comes from CAD (computer-aided design), which is then transferred to CAM (computer-aided manufacturing) software.

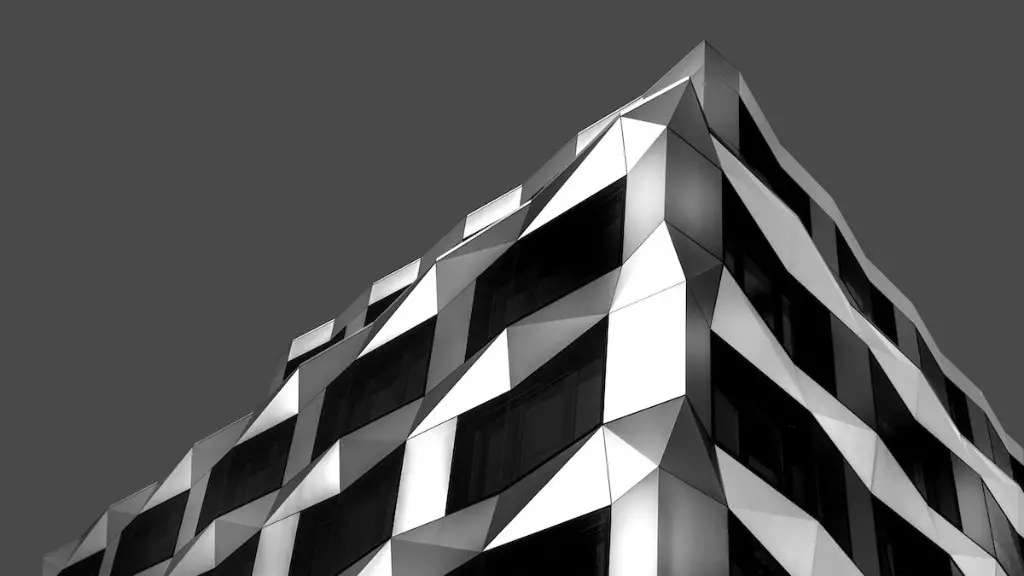

Digital fabrication has many advantages over traditional manufacturing processes. Perhaps the most significant advantage is that digital fabrication can produce very complex geometries that would be impossible to create using traditional methods. Additionally, digital fabrication is generally much faster and more efficient than traditional manufacturing, and can be easily scaled to meet changing production needs.

There are a few disadvantages to digital fabrication as well. One is that it can be expensive to set up a digital fabrication workflow, as the necessary equipment can be costly. Additionally, digital fabrication often requires highly trained personnel to operate, which can further increase costs.

Digital fabrication is a cutting edge technology that allows for greater control and accuracy in the manufacturing process. This method has sparked the interest of architects and product designers, as it opens the door to new possibilities in terms of solving complex processes and new approaches for mass construction.

What is fabrication architecture

A fabrication is an item that is manufactured off-site to the specification required for the project.

Digital fabrication is a great way for businesses to save time and money. The process is faster and cheaper, and it encourages creativity and customization. There is no price increase for making a one-of-a-kind product, which makes it a great option for businesses that want to offer unique products.

What are the 3 main fabrication techniques?

The three basic techniques of metal fabrication are cutting, bending, and assembling. These techniques are used to create a variety of products, from everyday objects to complex machinery. Each technique has its own set of challenges and benefits, and the best way to achieve the desired result is to use a combination of all three.

There are many different types of fabrication, but some of the most common methods include cutting, forming, punching, shearing, stamping, and welding. Each of these methods can be used to create different shapes and sizes of metalwork, and each has its own advantages and disadvantages.

Why is digital fabrication important?

Digital fabrication is a very efficient way to approach the production of the built environment. It enables designers to create new designs that are far more efficient than traditional methods. Additionally, digital fabrication provides many benefits to the environment, such as reduced waste and improved energy efficiency.

Digital fabrication technology has definitely changed the way we produce, construct, and even design things. The availability of digital and industrial technology has made a huge impact in this area. Additive manufacturing, 3D printing, and direct energy deposition are just some of the technologies that have made a big difference.

What is the role of a digital architect

A digital architect is someone who designs and oversees the construction of digital technologies. They work to ensure that these technologies are used in ways that will improve customer experience, increase profitability, and improve competitive position. Digital architects typically have a background in computer science or engineering, and they use this knowledge to help organizations make the most effective use of digital technologies.

Fabrication is the process of constructing products by combining typically standardised parts using one or more individual processes. For example, steel fabrication is the production of metal structures using a range of processes such as cutting, bending and assembling.

What are the examples of fabrication?

Examples of fabrication or falsification can include artificially creating data when it should be collected from an actual experiment, unauthorized altering or falsification of data, documents, images, music, art, or other work.

A single part drawing will depict all the information needed about the part. It shows the dimensions and scale of the part, as well as the material the part is made from.

Do architects use digital design

Over the past few years, architects have increasingly embraced technology and digital tools. Today, many architecture firms use various digital architecture tools—from design tools to workflow management tools—to create complex building models and floor plans with precision. This shift has helped firms become more efficient and productive, and has allowed them to create better-quality designs.

There several digital architectures that have been identified based on different computational concepts. Topological architectures are based on the concept of topological space, isomorphic architectures are based on the concept of isomorphic surfaces, motion kinematics and dynamics are used for animate architectures, and keyshape animation is used for metamorphic architectures. Each type of architecture has its own benefits and drawbacks, so it is important to choose the right one for the specific application.

What do architects use to make digital models?

The difference between BIM and CAD is that BIM is used to add information to 3D models, while CAD is used to create accurate representations of ideas and designs. BIM is often used in conjunction with CAD to create more detailed and accurate models.

Welding is a process of joining two separate metal parts. The process involves the use of high heat to melt the metal, which is then cooled to create a strong joint. Welding is a popular metal fabrication process among crafts enthusiasts because it is relatively easy to learn and can be used to create a variety of metal structures.

What are the four method of fabrication

Fabrication techniques are used to shape, cut or mold materials into items. Common fabrication techniques include cutting, forming, punching, stamping, shearing, and welding. These techniques can be used to create a variety of items, from small objects to large structures.

The topic is During the fabrication design stage, the designer and fabricator have to work together to make any necessary alterations to the product in order to address any conflicts between the initial design and the fabrication process that’ll be used to create the part.

Designers and fabricators need to be in close communication during the fabrication design stage in order to identify and resolve any potential conflicts between the design and the fabrication process. By doing so, they can avoid costly and time-consuming issues later on.

Final Words

Digital fabrication is a process whereby raw materials are converted into digital data, and then processed through a computer-aided manufacturing system to create a physical object.

Digital fabrication is a process that uses computer-aided design (CAD) and manufacturing (CAM) to create physical objects from digital models. It is a rapidly growing field that is revolutionizing the way things are made, and holds great promise for the future of architecture.